In the pharmaceutical industry, launching new products globally presents challenges, such as managing complex supply chains and efficiently meeting diverse market demands.

For the global launch of an innovative new medicine, a French pharmaceutical company partnered with Minerva Consulting to analyze and optimize their supply chain, which included all stages of production and distribution. The goal was to ensure the smooth delivery of a new medicine to four target markets: Europe, North America, China, and Japan for the period from 2024 to 2031.

The pharmaceutical company faced significant uncertainties while preparing to launch a new drug, particularly in managing its end-to-end supply chain.

For instance, the company doesn’t own manufacturing and distribution infrastructure. The French pharmaceutical business relies on raw material production and distribution partners. The supply chain involves a bulk manufacturer in France, a secondary manufacturer, and a factory in Italy.

When the product is ready, logistics service providers manage transit points and distribution centers across continents. Since the company’s target markets are spread globally, it must also consider different vehicles (truck and air cargo) and their characteristics.

The overall structure of medicine production and distribution

for end-to-end supply chain management (click to enlarge)

The end-to-end supply chain optimization would address the following:

Minerva Consulting used anyLogistix to run multiple simulation experiments to identify the best strategies for end-to-end supply chain optimization. The consulting company focused on:

The team conducted simulations with all alterations and different runs within one place — the anyLogistix software. This allowed for better comparison and analysis of key performance indicators (KPIs).

anyLogistix for end-to-end supply chain management and optimization (click to enlarge)

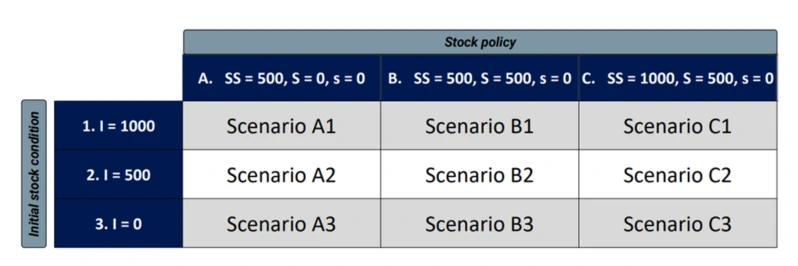

Using the bulk inventory policy variation analysis alone, the company tested nine different scenarios. To find the best policy, Minerva Consulting varied initial and safety stock numbers and desired inventory levels.

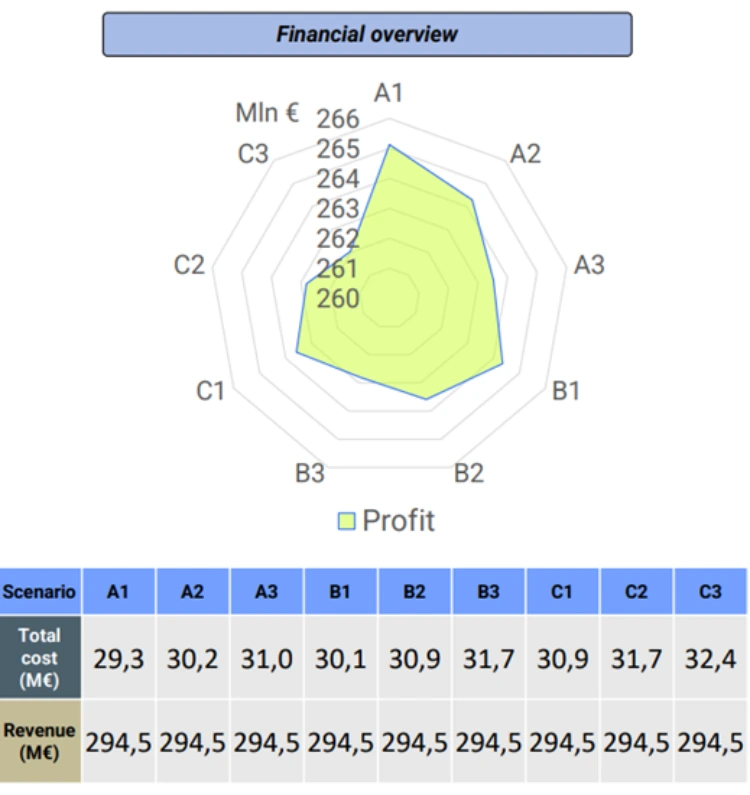

With the help of anyLogistix, it became possible to easily track impacted KPIs and identify the best scenario out of the nine options.

The optimal scenario (A1), where safety stock was set at 500 kg and initial inventory at 1000 kg, offered the best balance of cost efficiency and service level. This policy had the potential to minimize unnecessary bulk production while maintaining adequate stock levels for timely order fulfillment.

Possible scenarios with the bulk inventory policy variation analysis

Financial overview of possible scenarios

within the bulk inventory policy variation analysis

Another analysis of demand variation involved simulating multiple scenarios to understand the potential impact of fluctuating market demand. This analysis tested different demand coefficients, ranging from 0.6 to 1.5. It helped to assess how changes in demand would affect the production and supply chain performance for the forecasted period.

For building a resilient supply chain, the consultants performed the demand variation analysis and

forecasted costs, revenue, and profit (click to enlarge)

Through the bulk inventory policy variation analysis, Minerva Consulting identified the optimal inventory management strategy for the pharmaceutical company.

Given the low logistics volumes, Minerva Consulting recommended that a French company establish fixed-price contracts with logistics service providers. This approach would streamline accounting processes by eliminating the need to calculate the number of pallets handled. Since this practice is not cost-effective for small logistics volumes, it would be better to avoid it, especially in the first years of operation.

Demand variation analysis with anyLogistix helped check that the supply chain could efficiently handle both under- and over-demand scenarios. The consultants also ensured that the fulfillment rate remained 100% regardless of the scenario.

The simulation-driven approach that Minerva Consulting followed using anyLogistix drove cost-effective, resilient, and flexible end-to-end supply chain management. It will set the client’s business for success in the competitive pharmaceutical industry by building a resilient supply chain.

This case study was presented by Prof. Luigi Geppert, Minerva Consulting, at the anyLogistix Conference 2024.

The slides are available as a PDF.