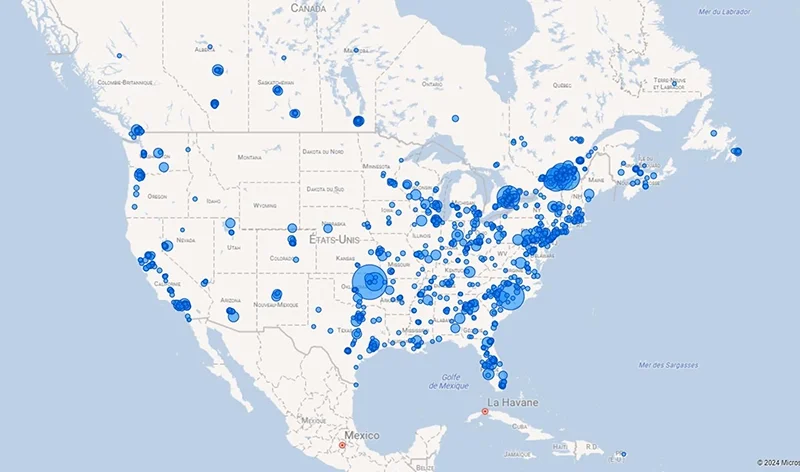

複雑な生産および物流ニーズを持つ業界にとって、効率的なサプライ チェーン管理は不可欠です。この資料では、SimWell Consulting が、リサイクル可能な包装材や紙製品を生産する北米の大手パルプ・製紙会社のクライアントの事例を紹介しました。同社は約 70 の製造拠点を運営し、数千人の従業員を抱えています。

クライアントネットワークの拡大

SimWell は、anyLogistix サプライ チェーン ソフトウェアを使用して、統合輸送計画と最適化のための貨物計画ツールを開発しました。

クライアントは 3 つの目標を設定しました:

既存の意思決定プロセスは手作業で時間がかかり、会社の競争力維持能力に影響を与え、業務を遅らせていました。

貨物計画ツールによる手動分析から自動化への移行

クライアントは、貨物計画ツールとして分析を自動化し、実装するためのデータ駆動型ソリューションを求めていました。彼らは、変化する需要、コスト、ストライキや新しい規制(制約)などの外部要因に動的に適応することを望んでいました。

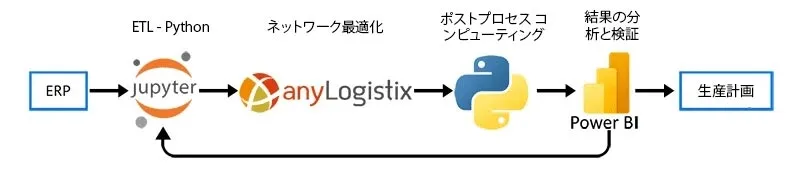

解決策としては、anyLogistix の機能と同社のERP (Enterprise Resource Planning) システムを組み合わせた貨物計画ツールの開発が挙げられます。このプロジェクトは、貨物輸送の計画とルートの最適化に重点を置いていました。コンサルタントは、最適な生産場所と輸送方法を決定することを望んでいました。主要な技術的要素には次のものが含まれます:

貨物計画ツール内のデータ循環のスキーム

SimWell は、カスタム ETL (Extract Transform Load) tool を使用して、手動入力や電子データベースを含む複数のデータベースからデータを抽出しました。このツールは情報を構造化し、anyLogistix で使用できるように準備しました。

こちらもお読みください: データ統合についての詳細、anyLogistix API を使用したデジタル ツインの構築に関するブログ。

コンサルタントは、Big M と anyLogistix の数学的定式化を使用して、固有のビジネス制約に対処しました。

The Big M メソッドは、人工変数を導入して不等式を含む制約を処理する線形計画法です。

プロジェクトでこれを使用するためのフローは、次の 2 つのステップで構成されます:

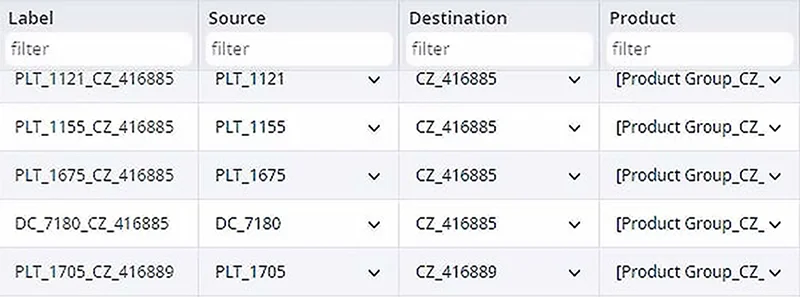

anyLogistix でのカスタム制約の実装

この制約により、顧客は複数の拠点から少なくとも 36,000 ユニットを調達することが保証され、限られた顧客は 1 つの拠点からのみ製品を調達することができます。

これまでの段階が成功したことで、SimWell はデータ処理時間を 8 ~ 12 時間から 4 時間に短縮する貨物計画ツールを開発しました。自動化により、分析結果の検証と実装がより迅速になりました。

SimWell は、Power BI を使用して結果を視覚化しました。このツールにより、専門家は結果を迅速に確認、検討し、生産および輸送の計画と最適化戦略に適用できるようになりました。

こちらもご覧ください: anyLogistix を使用してグリーンフィールド分析の結果をネットワーク最適化に変換し、その結果を Power BI で視覚化する方法を説明した SimWell のケーススタディ。

このプロジェクトにより、同社の輸送計画と最適化は大幅に改善されました:

このケースで有望な結果が得られたことから、同社は完璧さを追求することを決意し、SimWell は anyLogistix を使用したいくつかのアイデアを考案しました。その中には、データ構造のさらなる自動化、CO2 排出量,のより詳細な分析、およびサプライチェーン全体の回復力と相乗効果を高めるための全部門にわたるデジタルツインの統合が含まれます。

このケーススタディは、anyLogistix Conference 2024 で SimWell の Mathieu Bédard 氏、Ershad Jahagirdar 氏、Jean-Daniel Mathieu 氏 によって発表されました。

スライドは PDF として入手できます。